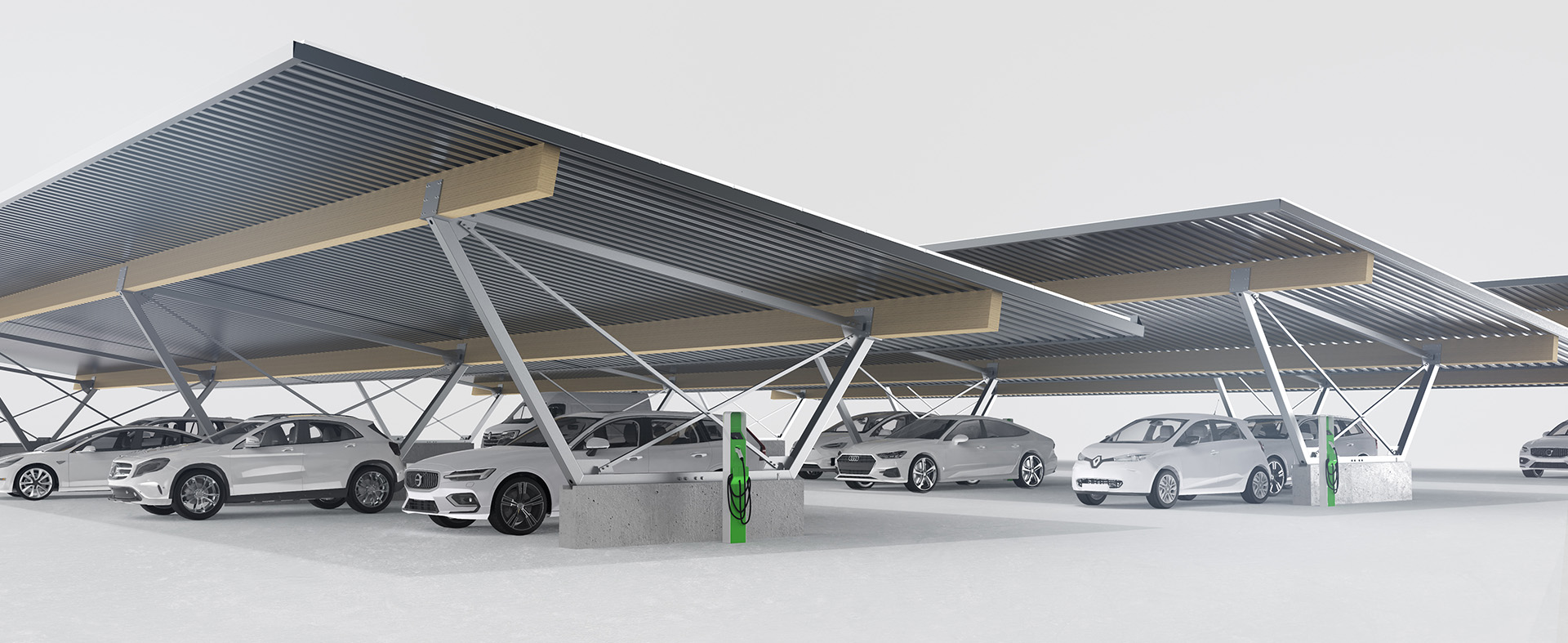

PMT CARPORT mit Photovoltaik

Ihre Systemlösung für eine wirtschaftliche Eigenstromerzeugung

Mit den Carport-Lösungen von PMT werden Asphaltwüsten der Großparkplätze dank wirtschaftlicher Eigenstromerzeugung sinnvoll genutzt. Die bewährte Rammpfahlgründung ermöglicht den Einsatz ohne aufwändige Oberflächeneingriffe und kostenintensive Fundamentarbeiten. Zudem überzeugen unsere Carports durch bedingungslosen Witterungsschutz für alle Fahrzeugtypen.

jetzt anfragen Scroll

Carport

Unsere Vorteile für Sie

Minimalinvasive Gründung

Geringer Eingriff in die Bestandsflächen. Bei PMT Carport ist kein aufwändiges Betonfundament nötig.

technische Daten Ganz nach Ihrem Geschmack

Wir übernehmen gerne CI-Anpassungen genau nach Ihren Vorstellungen.

Doppelt clever

Energiegewinnung für zum Beispiel Elektromobilität und überdachte Stellplätze in einer cleveren Lösung.

Produktmerkmale

PMT CARPORT bietet noch mehr Komfort, extra große Dachflächen und maximale Energiegewinnung. Auch bei Aufbau, Zubehör, Service und Sicherheit müssen Sie auf nichts verzichten.

Virtual showroom PMT CARPORT

Projektanforderungen

Wenn Sie sich für eine Carport-Lösung entscheiden, muss Ihr Parkplatz bzw. Ihre Fläche bestimmte Kriterien erfüllen, damit wir Ihr Projekt umsetzen können.

Wenn Sie sich für eine Carport-Lösung entscheiden, muss Ihr Parkplatz bzw. Ihre Fläche bestimmte Kriterien erfüllen, damit wir Ihr Projekt umsetzen können.

weiter lesen

Projektgröße

Eine wesentliche Rolle spielt die Größe des jeweiligen Projekts. Die Mindestanforderungen der für Projektgröße beträgt eine Gesamtleistung von 1.000 kWp oder 300 Stellplätzen.

Beschaffenheit der Carports

Auch wenn unsere Carports weitestgehend individualisierbar sind, gibt es einige Merkmale, die allgemein festgelegt sind. So ist es zum Beispiel nicht möglich, Carports ohne Blech oder ohne Beton zu fertigen.

Geographische Lage und Gelände des Parkplatzes

Um die Solarmodule auf den Carports möglichst effizient zu nutzen, muss Ihr Parkplatz einige geographische Anforderungen erfüllen. Er sollte sich auf einer möglichst ebenen Fläche befinden und keine Schrägen oder Hänge aufweisen. Carports auf Parkdecks oder an Gebäuden können wir aufgrund der Statik nicht realisieren. Auch eine übermäßige Verschattung durch zum Beispiel Bäume oder andere Gebäude würde gegen den Bau eines PV-Dach-Carports sprechen.

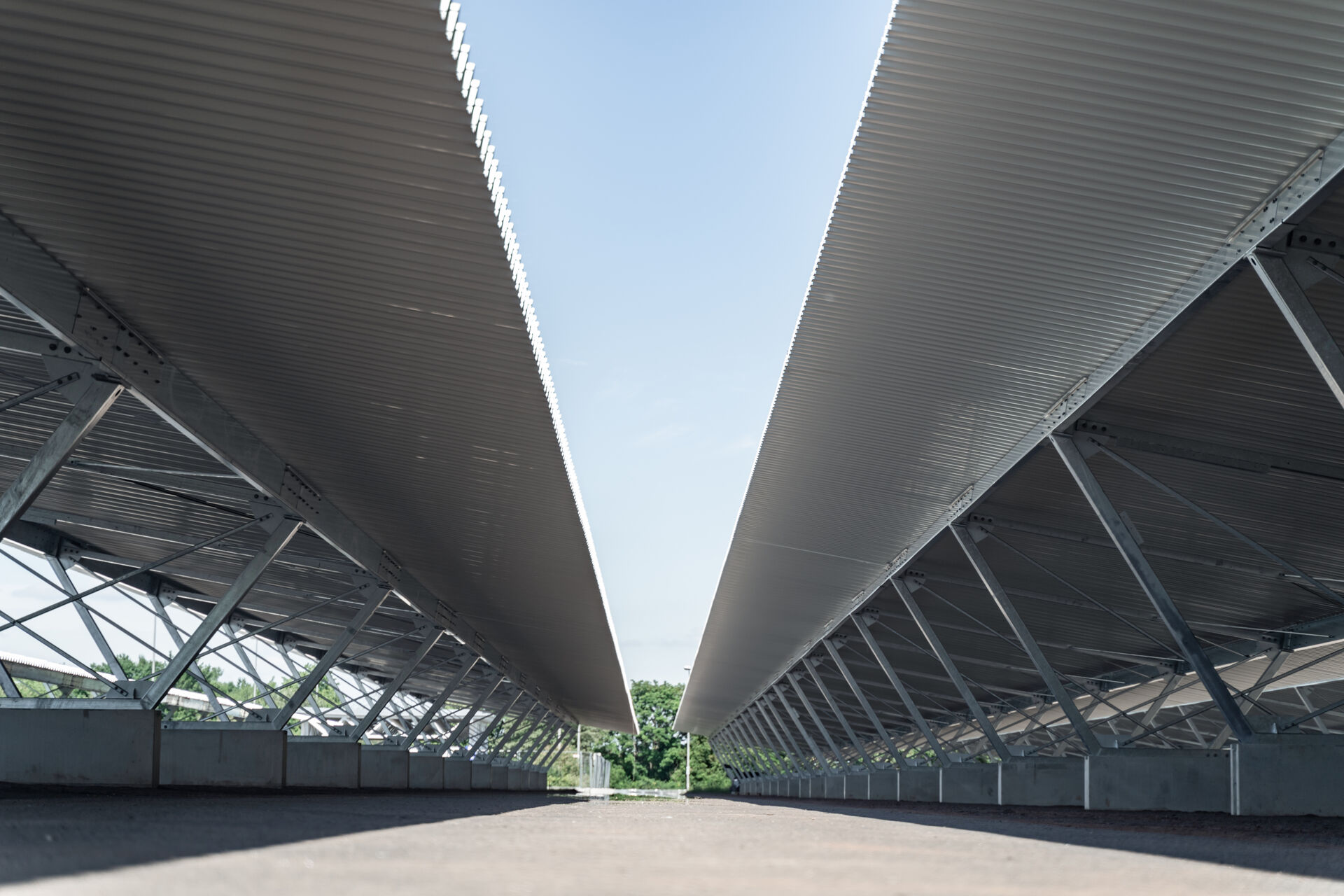

Galerie

Die wichtigsten Zahlen und Daten zu CARPORT Double auf einen Blick

Stellplätze

mind. 300 Stellplätze

Einfahrtshöhe

Double: 2,65 m/3,35 m/3,75 m/4,80m

Parkplatzbreite

individuell

Dachneigung

10°

Dachabmessungen

Double: Dachtiefe: 12,60 m bis max. 13,0 m, Länge variabel

Modulanzahl

individuell

Modulanordnung

vertikal/horizontal

Anfahrtsschutz

10 kN bei PKW bis 3,0 t

Kabelführung

integriert

Ich habe eine Frage zu diesem Produkt.

zum Service Maximale Prozesserfahrung Routine vom Auftrag bis zur Umsetzung

1

Anfrage

Nach Ihrer Anfrage mit den wichtigsten Grunddaten prüfen wir die Anforderungen und mögliche Einschränkungen.

2

Konzept und Kostenschätzung

Auf Basis der vordimensionierten Standardszenarien konzpieren wir einen Erstentwurf und liefern Ihnen einen Kostenvoranschlag. Zur besseren Abschätzung der Bodenqualität und statischen Vorbemessung klären wir offene Fragen.

3

Konkretisierung

Wir stellen Ihnen unser erstes Konzept vor und passen es nach Ihren Wünschen an. Anschließend gehen wir in die Konkretisierung über.

4

Finalisierung

Nachdem die Baugenehmigung Ihres Architekten vorliegt, beauftragen Sie uns parallel mit der Erstellung des finalen Layouts. Sie erhalten anschließend Ihr verbindliches Angebot.

5

Baugrund und Statik

Um die Dimensionierung und die finale Statik der Carports zu berechnen, werden Pfahlproberammungen und Probebelastungen von Geotechnikern ausgeführt. Gegenebenfalls erfolgen Anpassungen und eine externe Prüfung.

6

Angebot und Termin

Wir erstellen Ihr finales Angebot inkl. gewünschter Zusatzleistungen. In diesem Schritt wird auch die Terminplanung zur Umsetzung abgesprochen.

7

Lieferung und Umsetzung

Nach der Auftragserteilung liefern wir die Bauteile nach dem Bauzeitenplan. Sie beauftragen eine Montagefirma, welche auf Grundlage der Pläne die Carports aufbaut. Gerne senden wir Ihnen eine Liste unserer Partner zu.

SIE PLANEN EIN PROJEKT?

WIR BERATEN SIE GERNE

IHRE ANSPRECHPARTNERIN

Nadine Fiedler

Key Account Manager

+ 49 (0) 9225 95500 project@pmt.solutions jetzt kontaktieren

FAQ

Allgemeines

Gibt es die Möglichkeit, die Carports vorher zu sehen?

Gerne können Sie sich bei der Netzsch Arena in Selb oder bei dem P+R-Parkplatz der Stadtwerke in Bamberg einen Eindruck von unseren Carports im Einsatz machen. Auch bei Bosch in Eisenach können Sie unsere Carports nach Absprache mit dem Werksicherheits-Beauftragten ansehen.

Welche Faktoren könnten den Bau beeinflussen?

Generell können sich Verzögerungen bei der Baugenehmigung, externe Prüfungen und länderspezifische Normen auf die Bauzeit auswirken. Lagespezifische Herausforderungen wie Abstände zu anderen Gebäuden und Grundstücksgrenzen, Leitungs- und Kabelverläufe im Boden, Blendung durch eine Autobahn und Löschwasserzufuhren für zusätzliche Bauwerke können den Bau der Carports zudem beeinflussen. Durch die Qualität des Baugrundes, das Höhenprofil, Erdbebenlasten, Erschütterungen durch Rammarbeiten besteht auch die Möglichkeit, dass sich die Bauzeit verzögert. Zuletzt können durch Naturschutzvorschriften, Baumfällarbeiten und die Entwässerungssituation Änderungen in der Planung entstehen.

Lieferung & Leistungsumfang

Was ist in der Kostenschätzung alles enthalten?

- Gründung mit angenommener Einbindetiefe basierend auf vorbemessenen Lastszenarien

- Fertigbetonsockel mit Anschlusselementen, Vergussmörtel und Nivelliermörtel (bis maximal 6 cm Geländeausgleich)

- Feuerverzinkte Stahlkonstruktion mit Anschlusselementen

- Pfette (Holz/Stahl) mit Anschlusselementen

- Trapezeindeckung mit Anschlusselementen

Welches Zubehör kann zum Carport dazu bestellt werden?

- Blechdacheinfassung: Besteht aus Ortgangblech, Firstblech und Wasserprallblech bzw. Traufblech

- Schneefang: Ist ein alternatives Traufblech mit zusätzlicher Kantung, um den Schnee vom Abrutschen abzuhalten

- Entwässerung: Beinhaltet Kastenrinne (Nennmaß 333) mit Fallrohr (DN100) bis GOK und allen notwendigen Anschlusselementen. Dieses ist für ein Fallrohr an jeder zweiten Stütze kalkuliert (eine Entwässerungsbemessung ist Bauherrensache)

- Unterkonstruktion PV-Anlage: Beinhaltet Kurzschienensystem zur PV-Montage mit Schienen, Klemmen, Schrauben, Clips. Kabelbinder o. Ä. sind nicht enthalten.

Haben die Carports eine lange Lieferzeit?

In der Regel werden die Komponenten in einem Zeitraum von 6-8 Wochen geliefert. Anschließend beginnt die Montage auf den Parkflächen.

Ist die Montage schlüsselfertig?

Gerne begleiten wir Sie über den gesamten Prozess hinweg zu Ihrem perfekten Carportprojekt. Die Montage des Carports führt ein vom Kunden beauftragtes Montageunternehmen durch, dass die Anlage entsprechend schlüsselfertig übergibt. Eine Liste mit unseren Partnern lassen wir Ihnen gerne zukommen.

Ist die V-Rohrkonstruktion immer im Lieferumfang enthalten?

Ja, neben den V-Rohren liefern wir die 180 HEA-Träger, das vorgefertigte Beton-Sockelelement (gleichzeitiger Anfahrtsschutz), Ankerelemente, Ausgleichsmasse unter den Betonsockel sowie das Hochindustrietrapezblech für das Dach. Je nachdem für was Sie sich entscheiden ist die Holz- bzw. Stahlpfette ebenfalls inbegriffen.

Planung & Anträge

Wie läuft die Planung ab?

Nennen Sie uns die genaue Adresse, und zeigen Sie auf, wo sich die Parkfläche befindet bzw. wo sie entstehen soll. Geben Sie uns gerne die Anordnung der Carports und Ihre Anforderungen an die PV-Anlage weiter. Wichtig: Nennen Sie uns ggf. die Höchstmaße und Leistungsbeschränkungen des Standorts. Anschließend können wir eine erste individuelle Planung vornehmen.

Mit welchem zeitlichen Projektumfang muss ich rechnen?

Unserer Erfahrung nach müssen ca. sechs Monate für das Projekt veranschlagt werden. Das liegt nicht an der Lieferzeit oder den Vorplanungen, sondern vielmehr an notwendigen Bodenproben und anderen Zusatzthemen.

Muss für ein Carport ein Bauantrag gestellt werden?

Ja, Carports sind wie Gebäude zu betrachten und müssen vom Bauamt genehmigt werden.

Wer stellt den Bauantrag beim Bauamt?

Den Bauantrag beim zuständigen Bauamt stellt ein Architekt, welcher zur Einholung von Baugenehmigungen berechtigt ist. Der Architekt wird vom Kunden beauftragt.

Montage

Wer führt die Montage des Carportsystems durch?

Die Montage des Carports führt ein vom Kunden beauftragtes Montageunternehmen durch. Eine Liste mit unseren Partnern lassen wir Ihnen gerne zukommen.

Wer bestellt und montiert die PV-Module?

Die PV-Module werden vom Kunden bestellt und von der Montagefirma auf dem Carport-Dach montiert.

Was gehört alles zur Montage der PV-Anlage?

- die Montage der Unterkonstruktion

- die Verlegung der Stringkabel bis GAK oder Wechselrichter ohne Erdverlegung

- das Herstellen der Dacheinführung

- die Erdung der PV-Anlage (sofern notwendig)

- das Messprotokoll

- die Beschriftung der Strings

3D Modell

VR-SHOWROOM

Entdecken Sie unsere Photovoltaik-Montagesysteme in einer neuen Dimension. Erleben Sie unsere Produkte hautnah.

jetzt ausprobieren