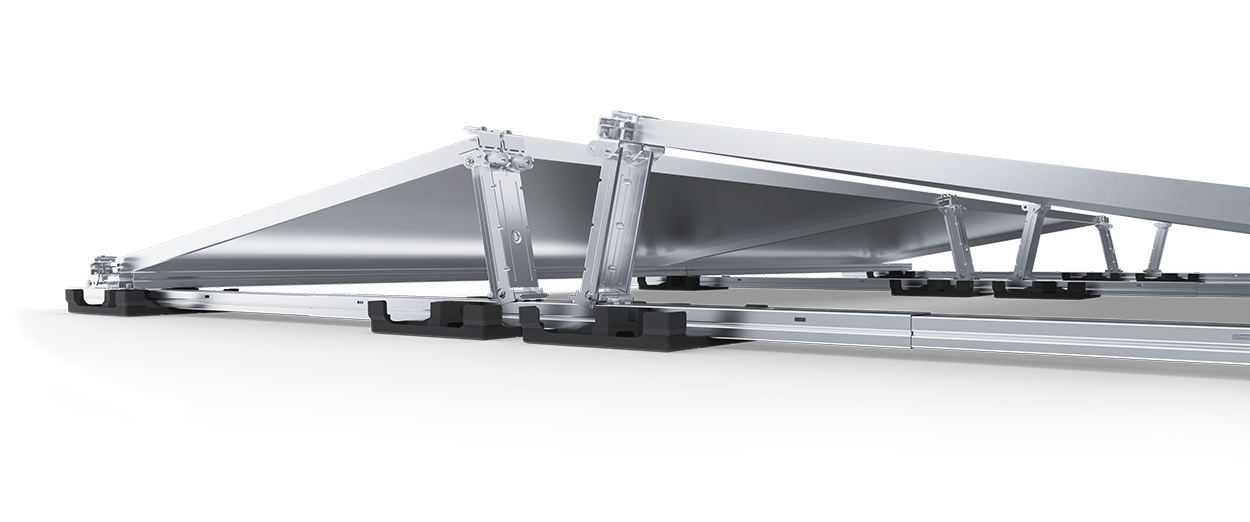

Photovoltaic flat roof mounting system

PMT X118 - Protection without limits

The assembly system that guarantees stability, efficiency and success. PMT X118, the mounting system that defies every challenge. Our innovative flat roof system revolutionizes through incomparable stability, efficiency in installation and unsurpassed cost-effectiveness. Our promise: Your project will be successful - guaranteed.

Request now

Scroll

PMT X118

LET US CONVINCE YOU

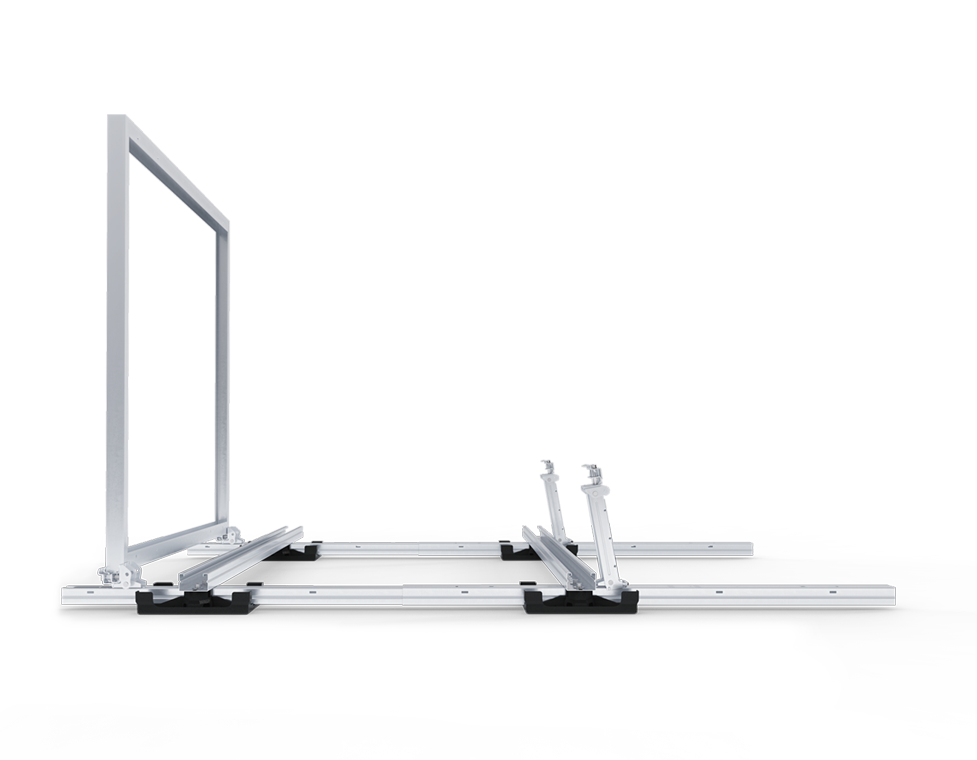

Simple assembly

The system enables simple and

and quick installation of the system.

Thanks to the innovative Push & Click

technology, future maintenance

maintenance work can be carried out quickly and

carried out quickly and easily.

Reliable throughout

The low acquisition costs,

the increase in electrification

and the extensive

and extensive warranty services enable

unsurpassed economic efficiency.

Unbeatable overall economy

PMT X118 is particularly suitable for

large modules. This allows

large projects even faster and

more efficiently.

Simple installation and top quality performance for your flat roof projects

PMT X118 is suitable for roof surfaces with a pitch between 0 and 10° and can be used in almost all European wind and snow load zones.

During the planning process, unused roof areas and disturbed areas are efficiently converted with PMT X118. The result is an optimized use of space, which in turn leads to increased energy production in relation to the existing roof area. As an additional benefit, we offer a 15-year guarantee for PMT X118, which also includes the EasyPlates.

During the planning process, unused roof areas and disturbed areas are efficiently converted with PMT X118. The result is an optimized use of space, which in turn leads to increased energy production in relation to the existing roof area. As an additional benefit, we offer a 15-year guarantee for PMT X118, which also includes the EasyPlates.

PMT X118 is suitable for roof surfaces with a pitch between 0 and 10° and can be used in almost all European wind and snow load zones.

During the planning process, unused roof areas and disturbed areas are efficiently converted with PMT X118. The result is an optimized use of space, which in turn leads to increased energy production in relation to the existing roof area. As an additional benefit, we offer a 15-year guarantee for PMT X118, which also includes the EasyPlates.

During the planning process, unused roof areas and disturbed areas are efficiently converted with PMT X118. The result is an optimized use of space, which in turn leads to increased energy production in relation to the existing roof area. As an additional benefit, we offer a 15-year guarantee for PMT X118, which also includes the EasyPlates.

read more

PMT X118 Quarter-point clamping

PMT X118 Edge clamping

Gallery

Type of application

Flat roof up to 10° roof pitch

Angle of attack

10°

Alignment

East-West

Roof covering

Foil (EPDM, PVC, TPO/FPO), bitumen, concrete

Standard step size

2384 mm / 2504 mm / 2629 mm / 2749 mm

Weight

System surface load incl. module and ballast from 12.5 kg/m²

EasyPlates

Plastic plate made of PE-HDGF 20 (high-density polyethylene)

No plasticizer migration

Material

Sheet steel S350GD / S550GD, coating ZM310

PE-HD

PV module suitability

All standard module sizes

Edge clamping

Length = 1,600 - 2,000 mm,

Width = 990 - 1,230 mm,

height = 30 - 40 mm

Quarter-point clamping

Length = 1,600 - 2,500 mm,

Width = 990 - 1,230 mm,

height = 30 - 40 mm

ARE YOU PLANNING A PROJECT?

WE WILL BE HAPPY TO ADVISE YOU

YOUR CONTACT PERSON

Nadine Fiedler

Key Account Manager

+ 49 (0) 9225 95500

project@pmt.solutions

Contact us now

FAQ

Frequently asked questions

What about the adhesive friction value, also on bitumen?

We recommend measuring the static friction coefficient for each project on a project-specific basis using the PMT measurement protocol and the PMT static friction coefficient backpack. The default value in the planning tool PMT PLAN is 0.5, which must be verified on a project-specific basis.

What heat and cold resistance do the plastic plates have?

The plastic disks for PMT X118 should be tested and approved for the same temperature resistance as the EVO 2.1. This means for temperatures between -20ºC and +80ºC.

Are there migration results for the plastic plates? Are film manufacturers involved?

As with the EVO 2.1, the plastic plate of the PMT X118 system is to be tested on various roof sealants (PVC, bitumen, EPDM, FPO/TPO).

Is a connection from 1° still recommended?

Furthermore, we recommend a connection to the roof from a roof pitch of 1º due to the thermally induced caterpillar effect. For this we recommend the BSW information paper, which we are happy to provide on request.

What is the material resistance of the plastic plates?

For this purpose, long-term abrasion tests are carried out for a service life of 25 years. In addition, UV tests are carried out to ensure appropriate durability.

How do I know where the plastic plates go?

The exact positioning can be found in the corresponding data sheets for the various floor rails.

Can I plan the system in the tool?

When the PMT X118 flat roof mounting system goes on sale, it will be possible to plan the system using our planning software PMT PLAN .

What are the warranty conditions?

15-year guarantee incl. EasyPlates

For which modules can PMT X118 be planned?

Module frame height: 30-40 mm

Module dimensions: 990 - 1230 x 1650 - 2450 mm

Module dimensions: 990 - 1230 x 1650 - 2450 mm